Life After Coal: An Inside Look at Fly Ash Cleanup and Environmental Recovery

Project Name: Tanners Creek Fly Ash Pond Closure, Lawrenceburg, Indiana

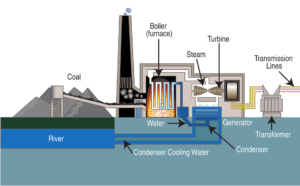

The Fly Ash Pond Closure and Environmental Remediation in Indiana at Tanners Creek is a key step in responsibly managing coal ash byproducts. Coal-fired power stations generate about a third of the world’s electricity, and one of their byproducts—fly ash—requires careful management to prevent environmental harm. Proper fly ash pond closure and environmental remediation are essential to protecting surrounding ecosystems and communities.

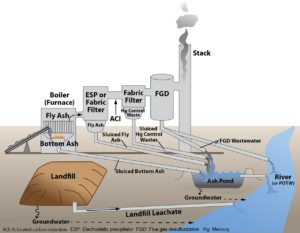

Dangers of Coal Ash

Long-term exposure to coal ash byproducts can lead to various health risks such as cancer, neurological and cardiovascular issues, and respiratory problems. Some additional concerns include environmental contamination and the negative impact on wildlife. Due to the consequential risks of coal ash byproducts, the Environmental Protection Agency (EPA) established regulations which include groundwater monitoring, safe disposal of coal ash, and closure requirements for existing ponds, basins, and landfills.

Coal Ash Management and Safety Measures

Site owners partner with Environmental consulting and engineering groups to remediate these existing disposal sites. This joint effort helps to minimize the impact that coal ash byproducts have on local communities, public safety, and maintain established guidelines by the EPA. Effective management of existing pond closures includes but are not limited to dewatering, site grading, installation of geosynthetic liners, soil cover systems, appropriate storm water drainage, monitoring compliance of regulatory standards etc.

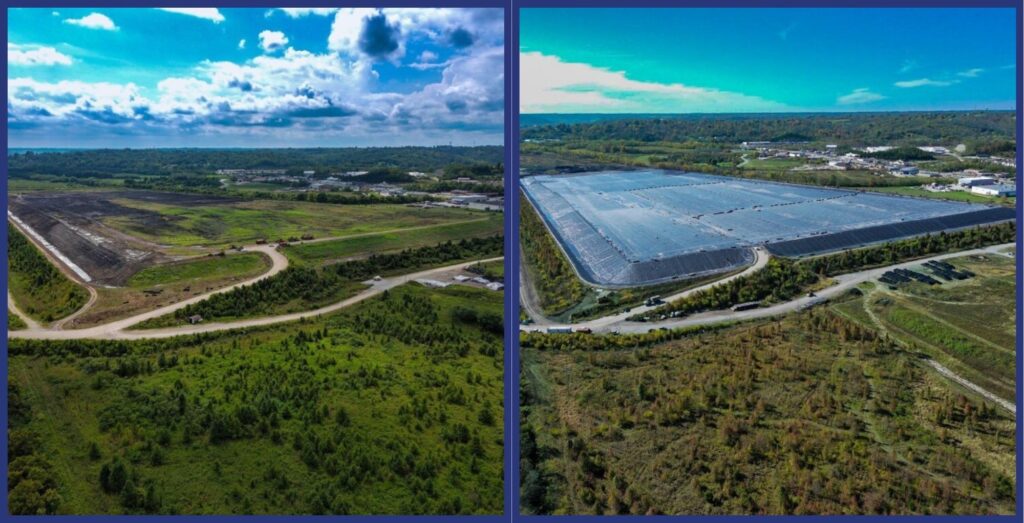

Patriot partnered with the site owner that is currently closing a former Fly Ash Pond in Lawrenceburg, Indiana associated with the former Indiana Michigan Power Company’s Tanners Creek Power Plant. The Indiana Department of Environmental Management (IDEM) approved the closure plan for the fly ash pond that includes the following key components: site grading, cover system, and storm water conveyance features. The site cover system placed over the fly ash pond is composed of geomembrane liner, a geocomposite drainage layer, and protective/vegetative soil cap. These key components were all designed to minimize rainwater infiltration into the fly ash thereby reducing potential impacts to the surrounding environment and community.

See the progress unfold in this timelapse of the project’s construction.

Managing environmental responsibilities doesn’t have to be overwhelming. Finding a qualified consultant who understands your unique needs and can guide you through complex environmental regulations is essential.

At Patriot, our experienced professionals help clients navigate every aspect of environmental compliance, site assessments, quality control, quality assurance, remediation, and landfill management. Concept to completion, Patriot provides practical, cost effective, and results-driven solutions that protect both your business and the environment.

About Patriot

Founded in 1995 to address the needs of the development and redevelopment community, Patriot specializes in environmental consulting, geotechnical engineering, and construction materials testing and inspection services. For more information about Patriot’s services or schedule a consultation, visit us here.

Call us at 317-576-8058 or email info@patrioteng.com to learn more.

Image Credits

(1) : By Tennessee Valley Authority – tva.com, Commons Archive